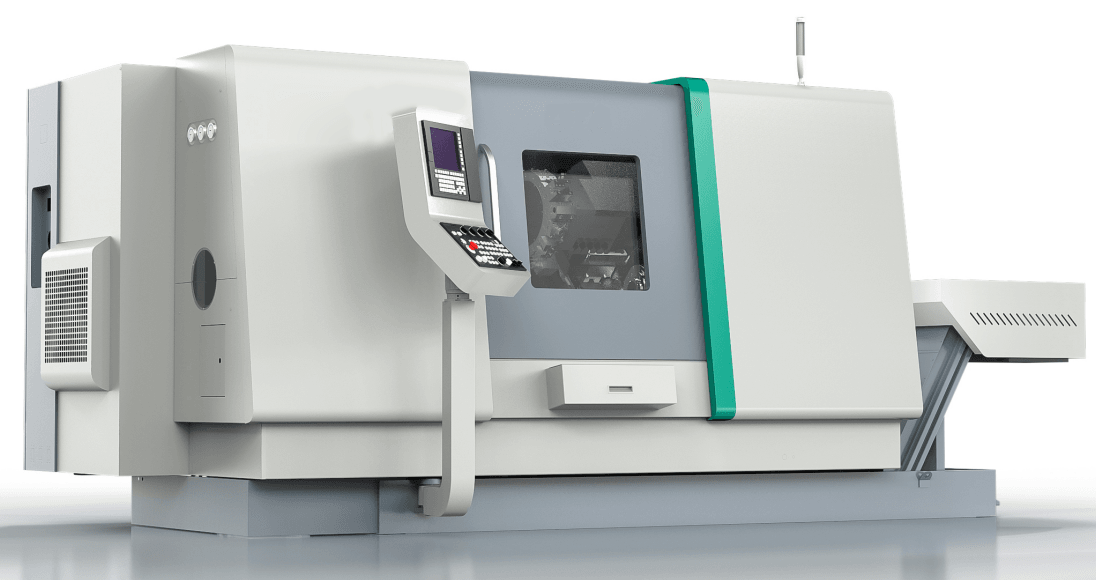

In the field of precision mechanical machining, efficient, high-precision, and high-rigidity processing equipment is the core competitiveness for enterprises to improve production capacity and product quality. The CT5 4-Axis Universal Turning Center launched by DRC combines core technologies such as the FANUC 0i-TF PLUS CNC system, tilted Y-axis design, 12-station BMT55 servo turret, and built-in sub-spindle. It is specially designed for the integrated high-precision turning, milling, drilling, and tapping of complex components, widely adapting to the mass production needs of industries such as automotive parts, aerospace accessories, precision instruments, and electronic components.

I. Core Technical Highlights: Redefining Precision Machining Efficiency

1. Top-Tier CNC System: Dual Guarantee of Operation and Precision

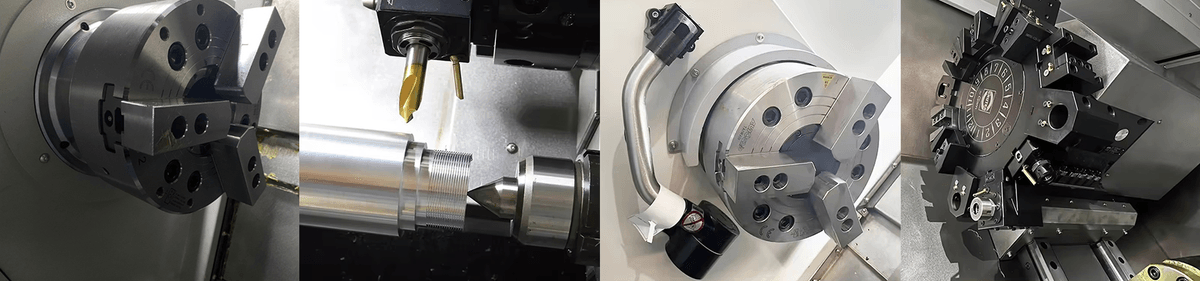

2. 4-Axis Linkage + Tilted Y-Axis: Expanding Machining Boundaries

3. High-Rigidity Structure + High-Dynamic Spindle: Stable Output of Strong Power

4. 12-Station BMT55 Turret: Efficient Tool Change and Multi-Functional Machining

II. Key Technical Parameters (Compliant with VDI 3441 Standard)

III. Standard Configuration and Optional Configuration

[Standard Configuration]

- Core System: FANUC 0i-TF PLUS CNC system (10" display + MGi)

- Spindle Unit: Main spindle A2-6 + built-in sub-spindle A2-5; Hydraulic 3-jaw chuck (D210mm)

- Turret and Tools: 12-station BMT55 servo turret; 4 fixed tool holders (2×OD tool holders + 2×boring tool holders)

- Auxiliary Equipment: Right-side chip conveyor with chip cart; 3-color signal lamp; Electrical cabinet heat exchanger

- Functional Systems: Automatic lubrication system; Coolant system; Hydraulic system; Chuck foot pedal

- Protective Devices: Fully enclosed protective cover (IP54 electrical cabinet; IP69K machine lamp)

[Optional Configuration]

- Driven tool holders (0° & 90°)

- Sub-spindle collet chuck set

- Sub-spindle 2-jaw chuck set

- Customized tooling and fixture solutions

IV. Application Scenarios and Core Advantages

Applicable Industries

Core Product Advantages

- High-Precision Stable Machining: Compliant with VDI 3441 acceptance standards, absolute measuring system + multiple compensation functions ensure batch production consistency;

- Efficient Composite Machining: 4-axis linkage + 12-station driven turret realize "one clamping, multi-process completion", reducing machining processes and errors;

- High Rigidity and Durability: 45° slant cast iron bed + linear guideway design, torsion and vibration resistance, extending equipment service life;

- Intelligent and Convenient Operation: FANUC system's user-friendly interface supports program copying and external storage execution, lowering operation thresholds;

- Flexible Adaptability: Rich standard configurations + optional modules, customizable upgrades according to machining scenarios.